As is the case in many industries, power electronics has been impacted by the Covid-19 pandemic. This includes a boost in new technologies and opportunities for power designers to capitalize on the benefits of E-learning. While it is always difficult to derive trends from large industries, as we get closer to APEC 2022, as a power engineer it is interesting to take a minute to ponder and consider what will contribute to making power supplies more efficient, more reliable and exciting to design.

Overall trends and technology

A major trend that we are all aware of is the 'electrification' and transition from fossil fuels to renewable energy. There are a lot of technological innovations required in this segment to reach the carbon neutral level expected by the European Commission, US DOE and similar initiatives in Asia. If we focus on what most of the power supplies companies are developing, I foresee that four trends, all of which will benefit from the implementation of Wide Band Gap Semiconductors, will influence the power industry in 2022:

- Reducing energy consumption

- Power supplies becoming part of the Machine-to-Machine eco-system

- Enhanced energy storage solutions

- Acceleration of harvesting energy solutions,

In the quest for reduced energy consumption, from harvesting energy to the grid, the power electronics industry is seeking new long term solutions to improve efficiency. International and local regulations have already forced power supply manufacturers to innovate, and we are seeing more stringent regulations under discussion that would require the power industry to further explore new topologies, components and materials.

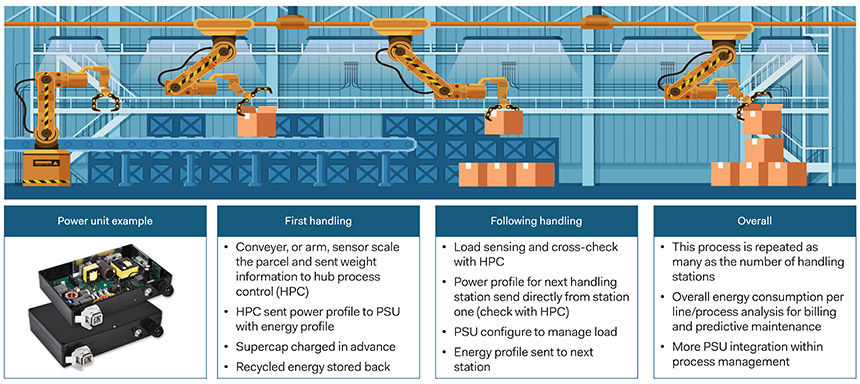

One example that illustrates and will benefit from this trend is E-commerce.

E-commerce was already growing before Covid-19, but as consequence of curfews, working at home, and the drastic reduction of physical interaction, it has grown exponentially, putting a high demand on shipping hubs, computerized storage and the overall supply chain. Before we even mention the associated datacenters required to manage the E-commerce process, there are the shipping hubs and warehouses that have become gigantic and consume lots of energy. Making these hubs more energy efficient has been on the agenda for all the major players, and the 2020-2021 peak on demand was a strong a signal for the need to reconsider the way to use and to manage energy.

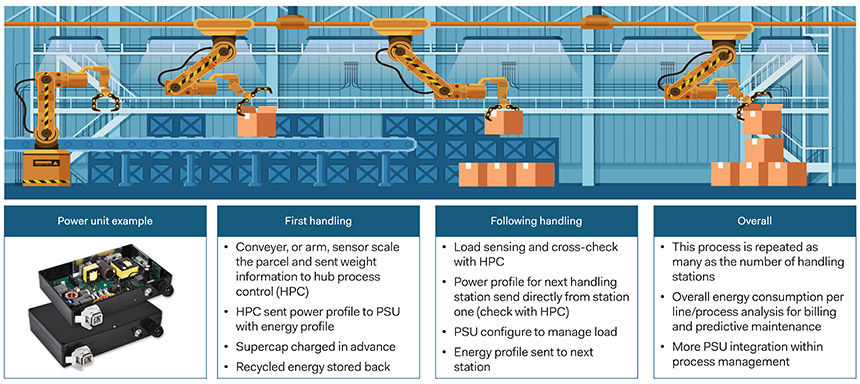

Figure 01: Smart Power operation in Smart Factory with machine-to-machine communication (Source: PRBX) |

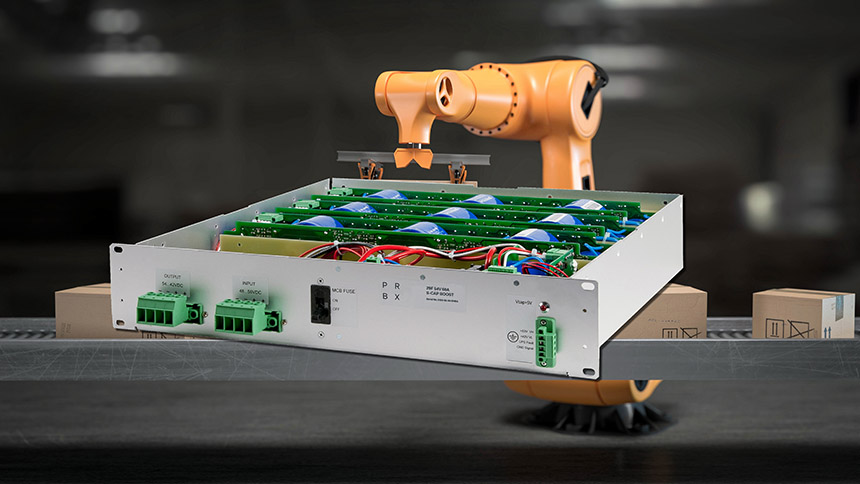

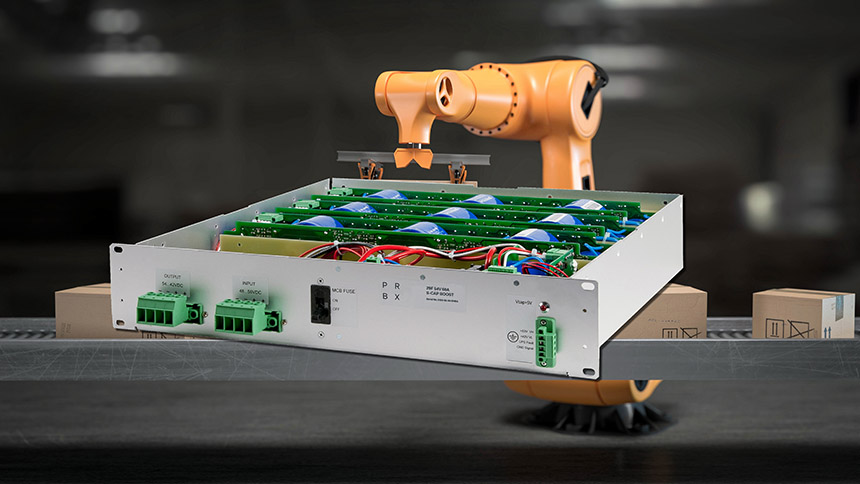

Power supplies as such are not consuming the majority of this energy, but, when one considers their strategic position in the operational chain, they become a key point in the overall process to optimize how energy is used in the complete chain. In 2022 we will see very advanced power supplies used in E-commerce handling and shipping hubs. Not only will they integrate higher levels of communication, they will also be able to store and restore energy from supercapacitors banks, reducing peak disturbances on the grid and consumption. Already experimented with in 2021, the power supplies have been integrated into a complete eco-system with Machine-to-Machine communication (Figure 01). They not only deliver power to a load e.g. conveyor motors, but they are able to sense and adjust the level of energy to store in local supercapacitors bank (Figure 02).

Figure 02 - PRBX S-CAP BOOST supercapacitors bank with digital control and communication

interface able to deliver peak energy to load and to store backward energy (Source: PRBX) |

Almost invisible, from the RFID inserted in the shipping box that will get power from RF signals, to sensors placed on motors or moving elements powered by vibration, micro-systems powered by harvested energy are developing very quickly. Additionally, the nanotechnology, such as nanotubes, make it possible to develop very small supercapacitors able to store enough energy to power sensors and transmitters.

To make this possible, the implementation of digital power and communication is a must, but the level of performance will also require power electronics engineers to design new power solutions with the so called 'Wide Band Gap' semiconductors. Depending on the application and voltage required they may select GaN or SiC types, but the benefits of WBG will contribute to making E-commerce more energy efficient and to reducing the carbon footprint.

Critical building blocks!

For decades the improvements in energy efficiency levels of power supplies have been made possible by technological evolutions. Moving from linear to switching technology was an early major one, followed by a number of more minor leap-frogs until digital power came to market.

Despite it having been on the market for several years, with the emerging WBG technology and the possibilities offered by those components, digital control becomes an absolute MUST and I strongly believe it will be a major building block for power designers when developing new products.

For components, the WBG transistors are without doubt the ones that will prevail in 2022. That said, conventional Power FETs are also making big progress and power designers will have to achieve new levels of business assessment and acumen when selecting the most appropriate technology for their applications.

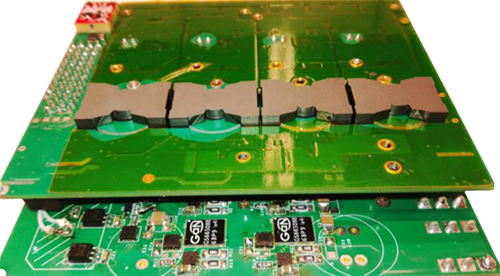

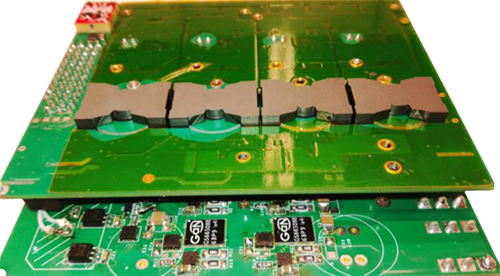

Figure 03 - PRBX multi-cores auto-tuned power converters with

advanced digital control and GaN FET transistors (Source PRBX) |

The third building block I foresee as important is the advanced planar transformer with interleaved multi-core technology. Not all power supplies require megahertz switching but considering the constant quest for smaller power supplies with higher efficiency, power designers will have to consider new types of transformers and new winding techniques. In that respect they will not only be helped by ferrite manufacturers developing new materials but also by Artificial Intelligence software that can shorten the time to design and test new transformer types (e.g., Frenetic, Simba).

One specific example of this is research currently being conducted at PRBX, combining digital control, GaN, and multicore transformers with advanced wiring and auto-tuned performance within the wide operational range that is seen in some industrial applications that require extremely wide input voltage ranges, as well as outputs subject to repetitive peak loads. Final products while not ready yet will not be possible without the combination of digital control, WBG and advanced magnetics (Figure 03).

I believe many of the new products that we will see in 2022 and onwards will be based on these three building blocks, which I'm sure will also include more communication to become part of a Machine-to-Machine ecosystem.

In WBG we trust!

One interesting aspect about Wide Band Gap semiconductors is that we are seeing a similar situation to when the first power MOSFETs were launched. Some immediately considered the benefits of the WBG, despite early products that were based on a depletion mode that required very specific drivers and were not very user friendly, it didn't take too long for power semiconductors manufacturers to provide 'easy-to-use' solutions.

It has now been more than five years since manufacturers first promoted the benefits of that technology but if the Go To Market is ready, the Go To Application for mass users still requires a certain amount of time.

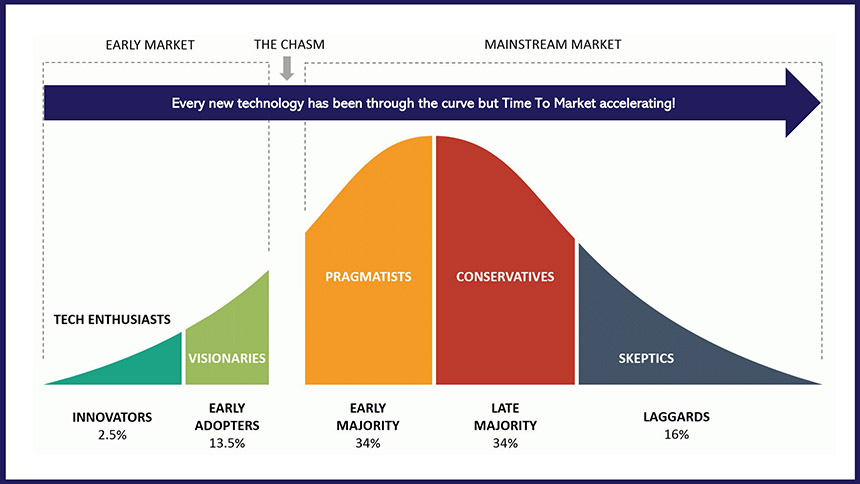

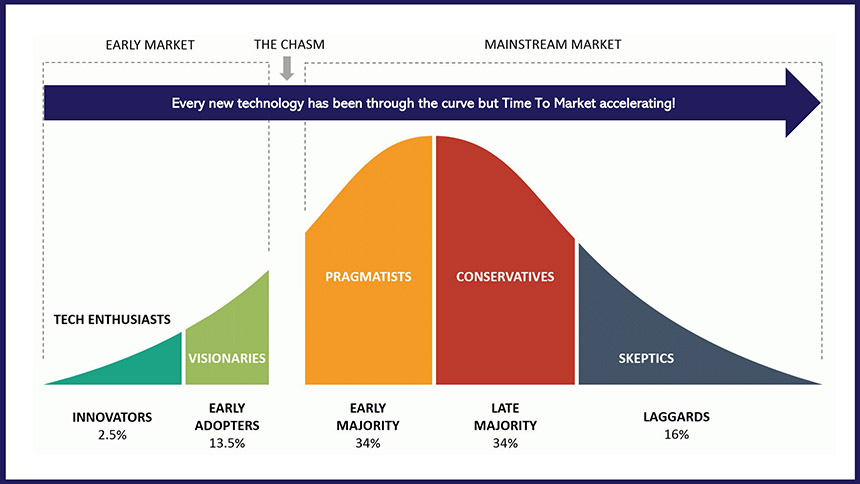

Figure 04 - Experienced power designers have crossed that technological chasm many times,

with the latest one being the migration from analog control to digital (Source: PRBX) |

We are all familiar with the 'camel-back' curve reflecting new technology adoption and crossing the chasm. Experienced power designers have crossed that technological chasm many times, with the latest one being the migration from analog control to digital, which took more than 10 years to reach a significant level of adoption (Figure 04).

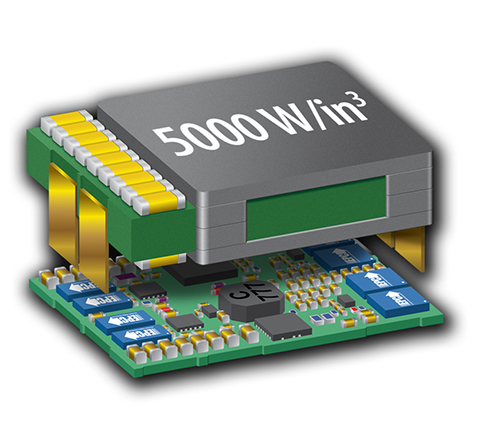

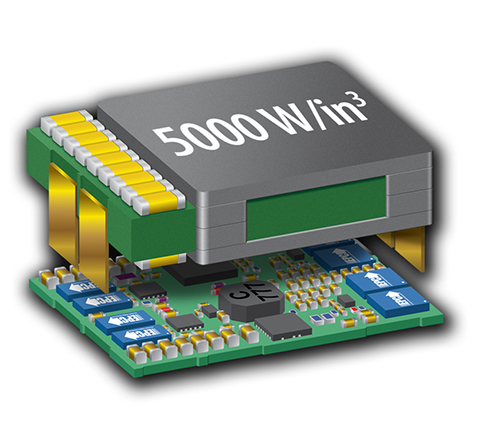

Figure 05 - Navitas' next-generation GaNFast power IC that will drive the 120W ultra-fast charger, contributing to reduce its size by 26% (Source PRBX/Navitas) |

Figure 06 - Efficient Power Conversion (EPC) approach is very interesting, minimizing interconnection losses, and making it possible to shrink a power converter to an unprecedented size (Source: PRBX/EPC)

|

In the case of WBG, and especially Gallium Nitride (GaN), early adopters entered the fray much quicker than some had predicted a few years ago. It is no surprise that the PC and Mobile/Nomad industries were some of the early adopters. The number of USB-C chargers using GaN semiconductors announced in 2020-2021 is very impressive. Particularly worthy of mention is Navitas' next-generation GaNFast power IC that will drive the 120W ultra-fast charger supplied 'in-box' with vivo's iQOO-brand flagship iQOO 9 Pro mobile phone, demonstrating the rapid adoption of GaN by the 'nomad' industry. But it is not just the electrical performance, using GaN also reduces the physical size by 26%, reaching a stunning 1.3W/cc power density, which is quite incredible (Figure 05).

While it took 10 years for digital power to become a de facto technology, it took only five years for WBG to reach a similar level.

What is interesting in the development of the WBG semiconductors is that due to the specificity of this technology, with very low internal resistance and the ability to switch very fast, the packaging is very important and we see a lot of innovation from manufacturers to offer optimized solutions. Technologywise the Efficient Power Conversion (EPC) approach is very interesting, minimizing interconnection losses, and making it possible to shrink a power converter to an unprecedented size (Figure 06).

Of note is the amazing number of technical webinars held during the Covid-19 era, not to mention the virtual APEC 2021. Many companies have taken that as an opportunity for their power designers to attend online training, and as a result some power-semiconductor companies have reported shipping up to 10 times more evaluation kits than before the pandemic days.

If we simplify the market into two segments: High voltage (using SiC) and Low voltage (using GaN), we see two different patterns. High voltage applications such as electric vehicles and solar are already familiar with SiC transistors, and for that segment it is no big revolution for power engineers to undergo a learning phase for the relatively new low voltage technology.

In conclusion

In many different ways we have all been affected by the pandemic, although looking back it has contributed to a boost in learning new technology and speeding innovation. Considering all of that, 2022 will be a very important year for WBG and we can expect many new power supplies (AC/DC and DC/DC) to be announced during the year. 2022 will be a very exciting year for all of us designing power solutions.

References:

Powerbox (PRBX): https://www.prbx.com/

Navitas Semiconductors: https://navitassemi.com/

Efficient Power Conversion (EPC): https://epc-co.com/epc

Frenetic https://frenetic.ai/

SIMBA https://simba.io/

Applied Power Electronics Conferences (APEC) https://apec-conf.org/

|

Provided by Patrick Le Fèvre

Chief Marketing and Communications Officer, Powerbox

|

|

|

Powerbox, one of Europe’s largest power supply companies, and for more than four decades a leading force in optimizing power solutions for demanding applications, announces it has consolidated its Swedish operations to a new facility located at Hägersten, South of Stockholm.

Powerbox, one of Europe’s largest power supply companies, and for more than four decades a leading force in optimizing power solutions for demanding applications, announces it has consolidated its Swedish operations to a new facility located at Hägersten, South of Stockholm.